Manufacturing and Analytical Characterization - Chemical

Category: Poster Abstract

(W0930-08-51) Linking 3DP Manufacturing with SIFT-MS Volatiles Organic Compound Analysis

Wednesday, October 25, 2023

9:30 AM - 10:30 AM ET

- EP

Elke Prasad, Ph.D. (she/her/hers)

University of Strathclyde

GLASGOW, Scotland, United Kingdom - EP

Elke Prasad, Ph.D. (she/her/hers)

University of Strathclyde

GLASGOW, Scotland, United Kingdom - EB

Ecaterina Bordos (she/her/hers)

University of Strathclyde

Glasgow, Scotland, United Kingdom - VL

Vaughan S. Langford, Ph.D. (he/him/his)

Syft Technologies Ltd

Christchurch, Canterbury, New Zealand - MP

Mark J. Perkins, Ph.D. (he/him/his)

Element Materials Testing Ltd.

Cambridge, England, United Kingdom - JR

John Robertson, Ph.D. (he/him/his)

University of Strathclyde

Glasgow, Scotland, United Kingdom - GH

Gavin Halbert (he/him/his)

University of Strathclyde

Glasgow, Scotland, United Kingdom

Presenting Author(s)

Main Author(s)

Co-Author(s)

Purpose: 3D printing (3DP) oral solid dose forms by Fused Filament Fabrication has gained increased interest in recent years. To facilitate efficient formulation and process development, some studies developed and implemented rheological and mechanical screening tests [1-3]. However, changes in the formulated polymeric system due to processing at elevated temperatures and shear have not been addressed. In this study, SIFT-MS Volatiles Organic Compound Analysis was employed to monitor a 3DP manufacturing process.

Methods: A 50% w/w Paracetamol formulation in Co-povidone (Plasdone™ S-630, Ashland) was processed at 130°C with a linear printing speed of 40 mm/s on a filament free 3D printer (Intellectual Property Office UK, patent application number 2101534.2). The tablet weight over time was monitored during the manufacturing process. SIFT-MS analysis mass scan from 15 - 400 m/z employing H30+, NO+ and O2+ reagents was performed during the manufacturing process on volatiles extracted from the vent port of the Hot-Melt-Extruder of the 3D printer.

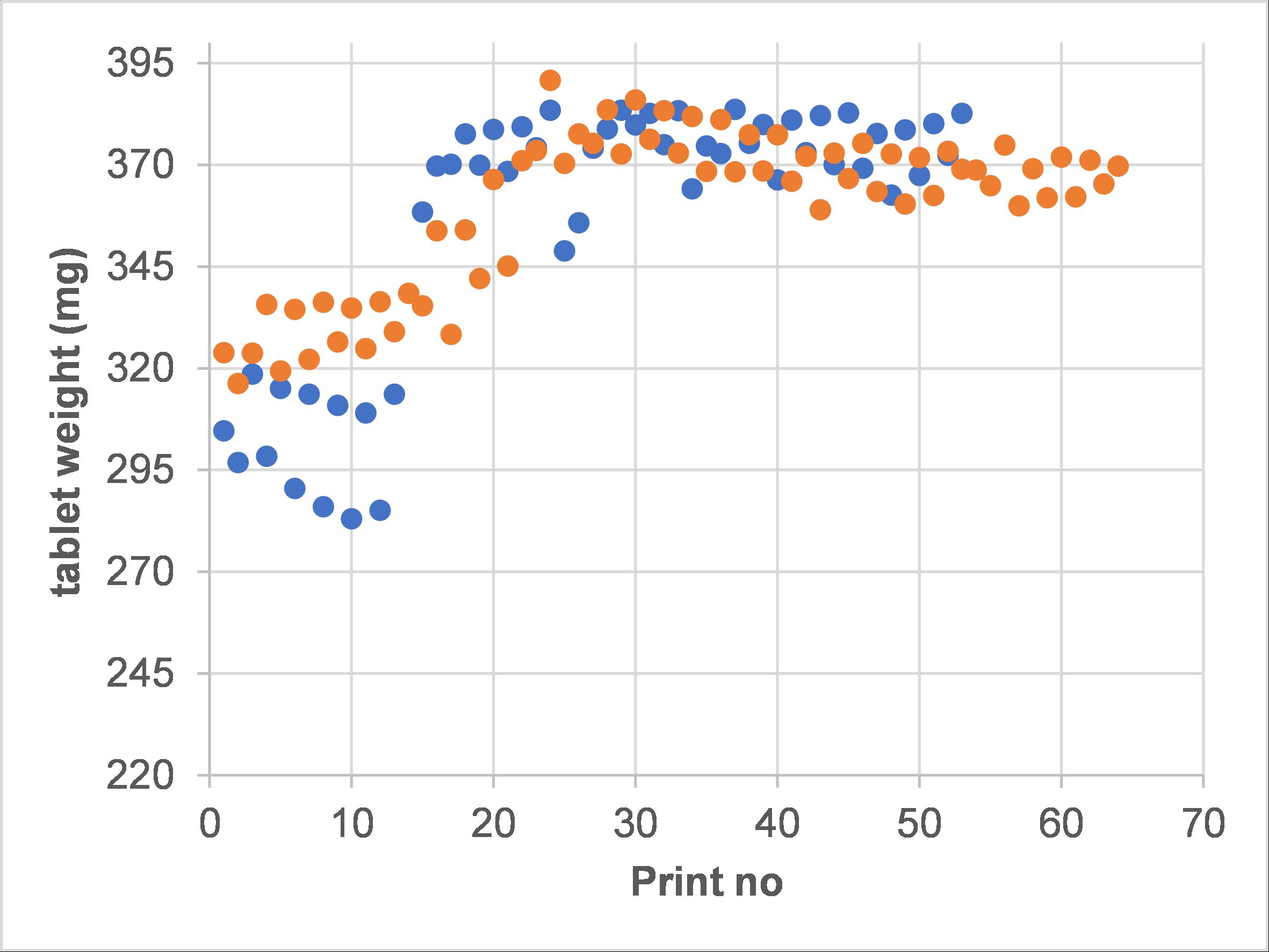

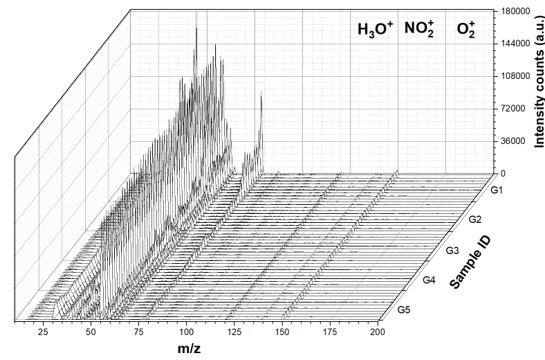

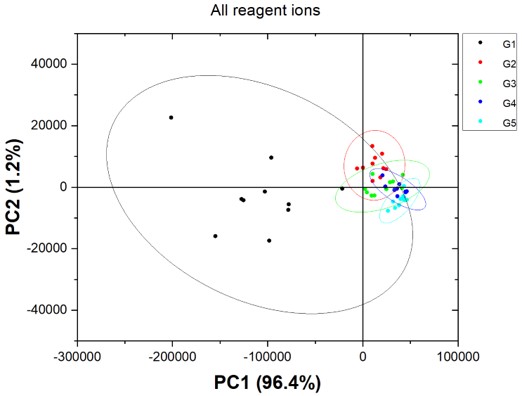

Results: 50% w/w Paracetamol - Plasdone S-630™ formulation processed on a filament free 3D printer showed an increase in tablet weight after 16 prints, which then remained stable (Figure 1). The change in weight coincided with a change in SIFT-MS products seen as a decrease in H30+ products (m/z 43+, 45+, 59+ and 79+), NO+ products (m/z 59+, 63+, 77+, 87+) and O2+ products (m/z 45+, 63+) (Figure 2). PCA analysis on sampling interval datapoints showed a clear difference of sampling interval G1 to all other sampling intervals (G2 – G 5) (Figure 3). Further studies are required to identify these products, the associated changes in the polymer system and the impact of manufacturing process conditions on these.

Conclusion: SIFT-MS analysis of a 3DP manufacturing process related a change in volatile organic compounds profile to changes in weight of the final pharmaceutical product.

References: [1] E. Prasad, J. Robertson, G.W. Halbert, Printability of pharmaceutical polymers in FDM 3D printers, Virtual PharmSci: APS international conference, Virtual, 2021,

[2] E. Prasad, J. Robertson, G.W. Halbert, Identifying the operating space and repeatability of a novel filament free FDM printer, AAPS 2022 Pharm Sci 360, Boston, MA, USA, 2022,

[3] E. Prasad, J. Robertson, G.W. Halbert, Quality control test for pharmaceutical feedstock material for FDM 3D printers, Virtual PharmSci: APS international conference, Virtual, 2021,

Acknowledgements: The authors would like to acknowledge that this work was carried out in the CMAC National Facility supported by the EPSRC (Grant ref EP/P006965/1) and by UKRPIF (UK Research Partnership Fund) award from the Higher Education Funding Council for England (HEFCE) (Grant ref HH13054). G. W. Halbert is funded by Cancer Research UK (C149/A20496). E. Bordos is funded by EPSRC Digital Design and Manufacture of Amorphous Pharmaceuticals project (Grant Ref: EP/W003295/1). We would also like to thank Ashland for the donation of polymer and Element Materials Testing Ltd, Colin Hastie and Syft Technologies Ltd for their support and the loan of the Syft-MS instrument.

Figure 1: 3DP tablet weight versus number of prints of a 50 % w/w PCM-Plasdone™ S-630 formulation processed at 130°C and linear print speed of 40mm/s: orange squares – manufacture run 1, blue circles – manufacture run 2.

Figure 1: 3DP tablet weight versus number of prints of a 50 % w/w PCM-Plasdone™ S-630 formulation processed at 130°C and linear print speed of 40mm/s: orange squares – manufacture run 1, blue circles – manufacture run 2. Figure 2: SIFT-MS mass scan (n=10) versus sampling interval (G1, G2, G3, G4, G5): Intensity counts (a.u.) versus SIFT-MS product mass charge ratio (m/z) for all reagents (H30+, NO+, O2+).

Figure 2: SIFT-MS mass scan (n=10) versus sampling interval (G1, G2, G3, G4, G5): Intensity counts (a.u.) versus SIFT-MS product mass charge ratio (m/z) for all reagents (H30+, NO+, O2+). Figure 3: Score plot of principal component 1 and 2 of all products of all reagent ions (H30+, NO+, O2+) and sampling intervals (G1 - G5).

Figure 3: Score plot of principal component 1 and 2 of all products of all reagent ions (H30+, NO+, O2+) and sampling intervals (G1 - G5).