Manufacturing and Analytical Characterization - Chemical

Category: Late Breaking Poster Abstract

(T1230-09-61) Optimization of the Continuous Direct Compression Process with Special Focus on Filling Devices

Tuesday, October 24, 2023

12:30 PM - 1:30 PM ET

Simon Schulte Herbrueggen

Doctoral Candidate

University of Hamburg

Hamburg, Hamburg, Germany

Simon Schulte Herbrueggen

Doctoral Candidate

University of Hamburg

Hamburg, Hamburg, Germany- AN

Anna Novikova

Fette Compacting GmbH

Schwarzenbek, Schleswig-Holstein, Germany - CL

Claudia Leopold

University of Hamburg

Hamburg, Hamburg, Germany

Presenting Author(s)

Main Author(s)

Co-Author(s)

Purpose: An optimal adjustment of the filling device of a rotary tablet press in dependence of the process parameters and powder characteristics is of great importance in Continuous Manufacturing (CM). The question arises whether the filling device has to take over both, powder homogenization and die filling, or whether a filling device geometry, which allows a direct powder flow, is sufficient. Previous experiments showed that a filling cone might have potential advantages in CM. The objective of the study was to identify optimal process settings as well as suitable filling device geometries for direct compression of a placebo powder blend in a CM environment.

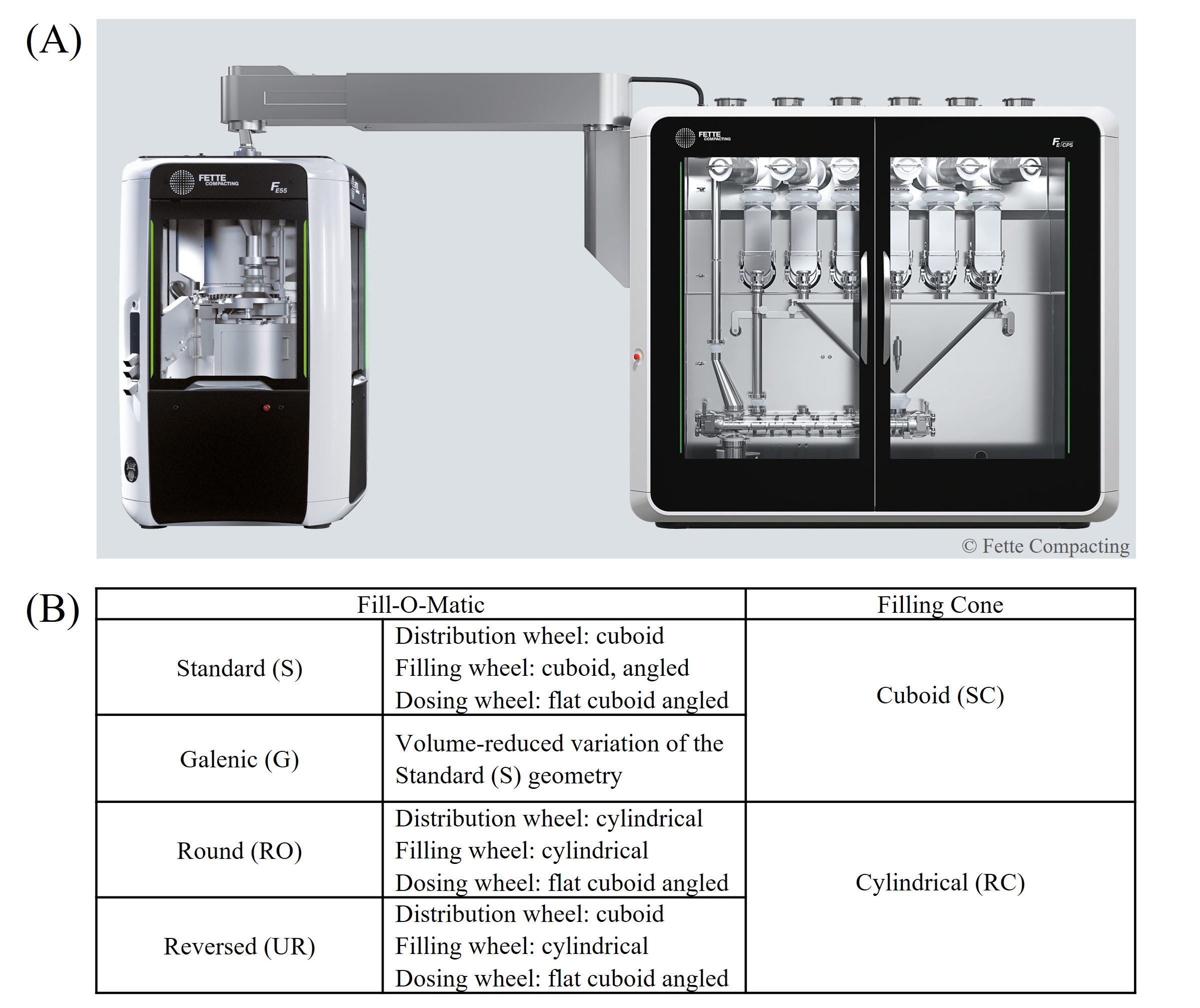

Methods: Experiments were carried out on a FE55 rotary tablet press connected to the Continuous Processing System FE CPS (Fette Compacting) (Fig. 1A). The tablet press was equipped with 60 pairs of faceted flat-faced punches with a diameter of 8 mm. Six filling device geometries (Fig. 1B), and three overfill levels (0.5/2.5/4.5 mm) were chosen as categorical factors. The numerical factors were, turret speed (10-100 rpm) and filling device speed, specified as a percentage function of the turret speed (90-130 %). The filling depth was kept at 7.5 mm. 41 design points were selected to be applied to a placebo powder blend. A lead time of 9 min was chosen, to ensure a steady state process. Within this time, the pre-, intermediate, and main compression forces were set to 2, 7, and 10 kN, respectively. The duration of each tableting run was determined by the production of 15,000 tablets. Every thousand tablets a sample of 5 tablets each were withdrawn and the compression force data was recorded after every hundredth tablet. To evaluate the tableting process, tablets of each sample were characterized regarding weight and tablet thickness. Tablet weight and its standard deviation (SD) as well as the SDs of the tablet thickness and the compression forces of each pressure roll were selected as quality parameters. The quality parameters were preprocessed by Z-Score normalization and analyzed by principal component analysis (PCA).

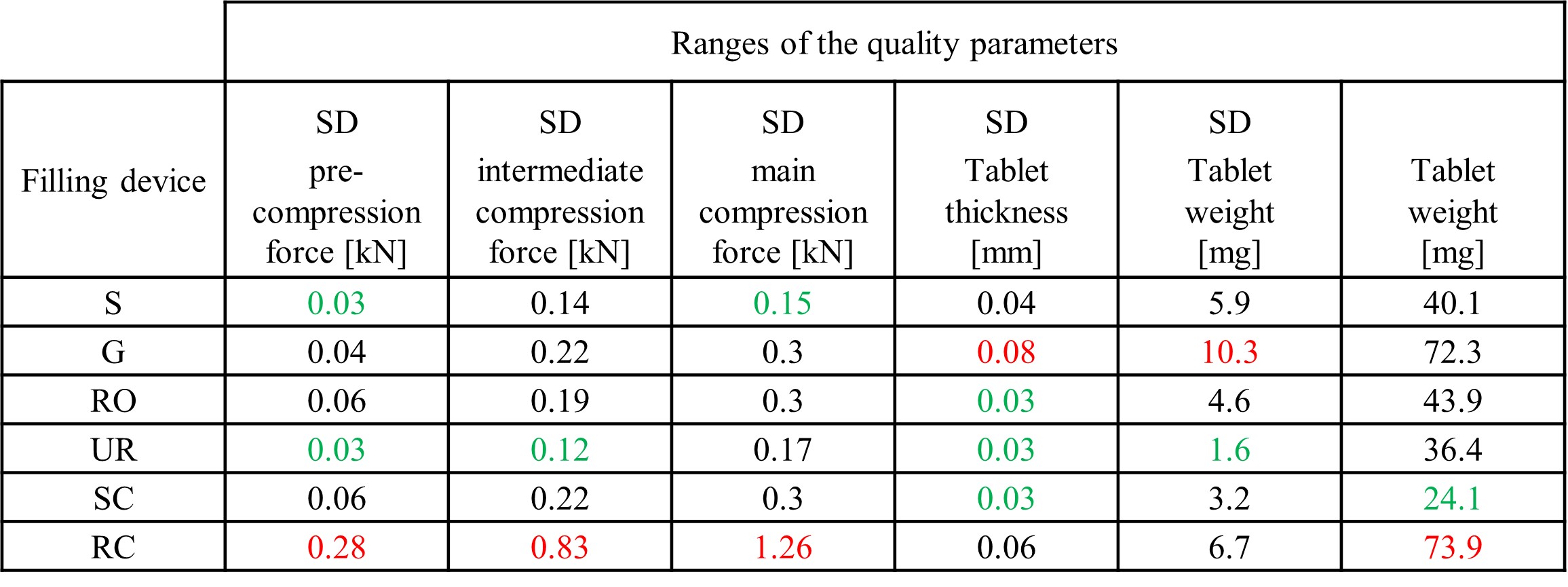

Results: Quality parameter ranges were calculated for each filling device (Table 1). The filling cone with cylindrical geometry (RC) showed the highest range of the quality parameters. In contrast, the reversed configuration (UR) exhibited low ranges. These results were confirmed by PCA (Fig. 2). The loadings of the first principal component (79 %) separate the tablet weight from the SDs of the quality parameters. The loadings of the second principal component (16 %) differentiate between the SDs of the tablet weight and thickness with negative values, and the SD of the compression forces and the tablet weight with positive values (Fig. 2A). Data from UR geometry experiments are clustered at low SDs and high tablet weight, whereas those with the RC configuration are strongly influenced by the process parameters, primarily the turret speed. In Fig. 2B, the center points of the experiments are highlighted. With these specific process parameters, it is apparent that the RC filling device is less suitable for die filling of the placebo powder than the other geometries. To illustrate the influence of the process parameters at high turret speeds, subsections of the PCA are displayed to highlight trends. In Fig. 2C the three geometries Reversed (UR), Filling Cone Cuboid (SC), and Standard (S) at the maximum turret and filling device speeds are shown. These settings result in a higher tablet weight with the UR and SC geometries and in significantly lower SDs with the UR geometry. With the SC geometry, an increase of the overfill from 0.5 to 2.5 mm and of the filling device speed from 91 to 130 rpm results in lower SDs and an increased tablet weight. With the UR geometry, an increase in the filling device speed leads to an increase in the tablet weight and to a reduction in the SDs at high turret speeds (Fig. 2D). An increase of the overfill must be considered in relation to the filling device speed, as the results indicate that there is an optimum of the quality parameters which can be achieved by the interaction of these two factors.

Conclusion: Depending on the filling device geometry, the overfill and the filling device speed have different effects on the quality parameters. Overfill and filling device speed must be considered in relation to each other. The data suggests, that there are optimal combinations of these parameters dependent on the applied geometry. The UR geometry is the best-suited Fill-O-Matic configuration for die filling of this powder, with a high tablet weight and low SDs within the defined ranges of the design. The RC geometry performed worse with increasing rotational speed compared to the SC geometry which yields good results during die filling with the placebo powder.

Fig. 1: (A) Continuous Processing System FE CPS; (B) Schematic representation of the filling devices geometries (UR is operated with reversed rotational direction of the distribution and filling wheel).

Fig. 1: (A) Continuous Processing System FE CPS; (B) Schematic representation of the filling devices geometries (UR is operated with reversed rotational direction of the distribution and filling wheel). Table 1: Ranges of the quality parameters for each filling device. The lowest range is displayed in green, the highest range in red. SD: Standard deviation

Table 1: Ranges of the quality parameters for each filling device. The lowest range is displayed in green, the highest range in red. SD: Standard deviation .jpg) Fig. 2: Principal component analysis (PCA). (A) Loadings and Scores Plot. (B) Scores Plot: Design center points at 55 rpm turret speed, 61 rpm filling device speed, 2.5 mm overfill. (C) Scores Plot: UR/SC/S geometries at 100 rpm turret speed, 130 rpm filling device speed, 2.5 mm overfill (100 | 130 | 2.5 UR/SC/S); SC geometry at 100 rpm turret speed, 91 rpm filling device speed, 0.5 mm overfill (100 | 91 | 0.5 SC). (D) Scores Plot: UR geometry at 100 rpm turret speed, 130 rpm filling device speed, 2.5 mm overfill (100 | 130 | 2.5 UR); 100 rpm turret speed, 110 rpm filling device speed, 4.5 mm overfill (100 | 110 | 4.5 UR); 100 rpm turret speed, 90 rpm filling device speed, 2.5 mm overfill (100 | 90 | 2.5 UR).

Fig. 2: Principal component analysis (PCA). (A) Loadings and Scores Plot. (B) Scores Plot: Design center points at 55 rpm turret speed, 61 rpm filling device speed, 2.5 mm overfill. (C) Scores Plot: UR/SC/S geometries at 100 rpm turret speed, 130 rpm filling device speed, 2.5 mm overfill (100 | 130 | 2.5 UR/SC/S); SC geometry at 100 rpm turret speed, 91 rpm filling device speed, 0.5 mm overfill (100 | 91 | 0.5 SC). (D) Scores Plot: UR geometry at 100 rpm turret speed, 130 rpm filling device speed, 2.5 mm overfill (100 | 130 | 2.5 UR); 100 rpm turret speed, 110 rpm filling device speed, 4.5 mm overfill (100 | 110 | 4.5 UR); 100 rpm turret speed, 90 rpm filling device speed, 2.5 mm overfill (100 | 90 | 2.5 UR).