Formulation and Delivery - Chemical

Category: Late Breaking Poster Abstract

(M1330-03-21) Developing Degradable Microparticles for the Delivery of Inactivated H1N1 Virus and NKT Cell Agonist for Single Dose Vaccination

Monday, October 23, 2023

1:30 PM - 2:30 PM ET

Zachary Sparks, MA

Graduate Research Assistant

Colorado School of Mines

Golden, Colorado, United States

Zachary Sparks, MA

Graduate Research Assistant

Colorado School of Mines

Golden, Colorado, United States- YW

Yuhan Wen, B.S.

University of Florida

Gainesville, Florida, United States - AC

Anuj Chauhan, Ph.D.

Colorado School of Mines

Golden, Colorado, United States - JD

John Driver, Ph.D.

University of Missouri

Columbia, Missouri, United States

Presenting Author(s)

Main Author(s)

Co-Author(s)

Purpose: Increasing the duration of antigen exposure and vaccine potency are imperative to developing effector and memory cells that provide longer protective immunity against invading pathogens. To provide prolonged antigen availability and eliminate the requirement of booster doses, polymeric microparticles may be used to deliver UV inactivated influenza virus with natural killer T cell agonist, α-GalCer. By optimizing microparticle formulation properties, antigen and adjuvant release may be modulated to achieve desired immune response in vivo.

Methods: Microparticle formulations were synthesized using double emulsion solvent evaporation technique to encapsulate 1) UV killed virus (H1N1 influenza A/PR/8/34), 2) UV killed virus + NaOH, 3) α-GalCer, or 4) UV killed virus + α-GalCer. Synthesis parameters of 1) polymer molecular weight, 2) polymer hydrophobicity, 3) polymer concentration in the organic phase, and 4) amount of inactivated virus were varied, and formulations were characterized by vaccine and agonist loadings and release profiles. Formulations included PLGA 50:50 (2-6, 7-17 kDa), PLGA 75:25 (4-15 kDa), and PLGA 75:25 (4-15 kDa)/PCL (14 kDa) 50/50. Virus and α-GalCer loading and release profiles were measured using hemagglutinin (HA) enzyme linked immunosorbent assay (ELISA) and liquid chromatography mass spectroscopy (LCMS). Formulations of virus + NaOH (co-encapsulated) and virus + α-GalCer (co-encapsulated) were tested in vivo in mice for cytokine, antibody, and T cell response and survival studies.

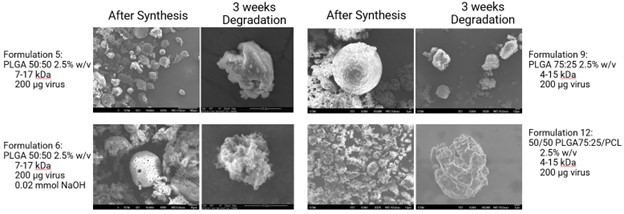

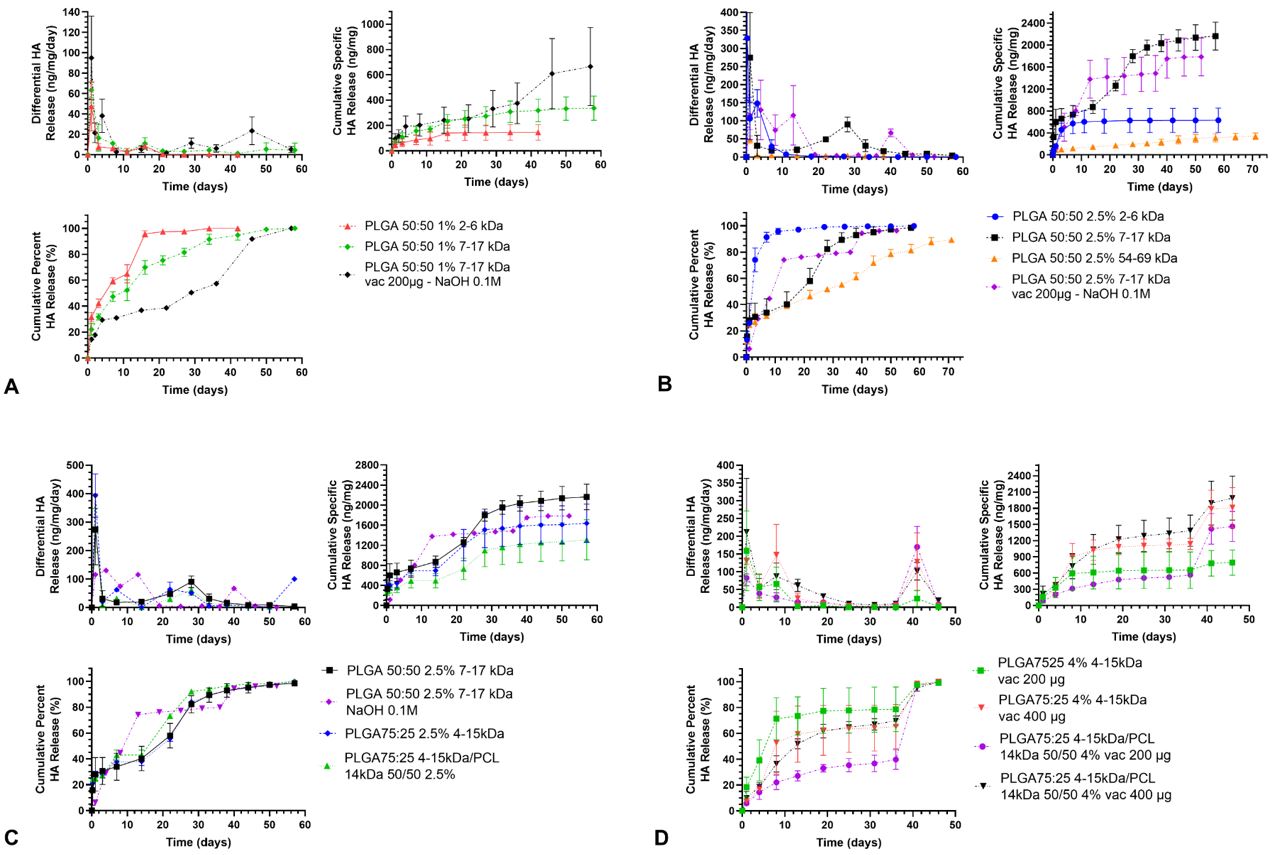

Results: Optical microscope and SEM images showed microparticles in the range of 15-30 μm for all formulations. In vitro loading measurements showed that PLGA 50:50 (7-17 kDa 2.5% w/v) formulation had the highest loading of 2200 ± 282 ng/mg HA (~6.1 ± 0.8 μg/mg virus) which is about 34% and 68% higher than PLGA 75:25 and PLGA 75:25/PCL particle formulations, respectively. Co-encapsulation of UV killed virus + NaOH in PLGA 50:50 (7-17 kDa) contained 665 ± 309 ng/mg HA (~1.85 ± 0.86 μg/mg virus) and 1851 ± 310 ng/mg HA (~5.14 ± 0.86 μg/mg virus) for 1% and 2.5% w/v polymer concentration in organic phase. Co-encapsulation of UV killed virus + α-GalCer in PLGA 50:50 (7-17 kDa, 1% w/v) contained 2009 ± 440 ng/mg HA (~5.58 ± 1.22 μg/mg virus) and 6.0 ± 0.28 μg/mg α-GalCer. The release profiles of the inactivated virus loaded particles in PLGA 50:50 and PLGA 75:25 formulations were similar with nearly constant rate of release over the duration of ~50 days. Both formulations showed a burst release between 23 and 28 days, but PLGA 50:50 formulation showed a 70% greater burst release of 2.7 μg/mg inactivated virus. Co-encapsulation with NaOH increased the rate of release in PLGA 50:50 (7-17 kDa) formulation due to faster degradation of the particles. α-GalCer only loaded particles were only tested in PLGA 50:50 7-17 kDa which gave ~38% release through seven weeks. Co-encapsulated UV killed virus + α-GalCer PLGA50:50 particles released 100% virus in ~15 days, whereas α-GalCer release was only ~49% in the same period. PLGA 50:50 (7-17 kDa, 2.5% w/v) formulation had higher loading and longer release (~50 days) compared to PLGA 50:50 (2-6 kDa, 2.5% w/v) formulation (633 ± 222 ng/mg HA, release over ~7 days).

Conclusion: Polymer concentration of the organic phase and polymer molecular weight were determined as the most critical parameters in vaccine loading. It was expected that increasing polymer hydrophobicity would give more sustained antigen release. However, this was not the case as the release rates between particles of PLGA polymer with different lactide to glycolide ratios were not found to be significantly different nor were the release rates between PLGA and PLGA/PCL blended particles. Based on the findings for the vaccine only, agonist only, and vaccine-agonist co-loaded formulations, in order to increase vaccine potency with lasting antigen availability, delivery of α-GalCer on a similar time scale as vaccine may be achieved by mixing virus loaded particles and co-encapsulated virus and α-GalCer loaded particles.

Acknowledgements: This project is supported by grants from Dept. of the Army – U.S. Army Medical Research Acquisition Activity (USAMRAA) (W81XWH-19-1-0005). Conflict of interest: None.

Figure 1. SEM images of vaccine loaded particles after synthesis and after 3 weeks of release. Top left) PLGA5050 2.5% 7-17 kDa (form. 5), Bottom Left) vaccine-NaOH loaded PLGA5050 2.5% 7-17kDa (form. 6), Top Right) PLGA7525 2.5% 4-15 kDa (form. 9), Bottom Right) PLGA7525 / PCL 50/50 2% 4-15kDa / 2% 14 kDa (form. 12).

Figure 1. SEM images of vaccine loaded particles after synthesis and after 3 weeks of release. Top left) PLGA5050 2.5% 7-17 kDa (form. 5), Bottom Left) vaccine-NaOH loaded PLGA5050 2.5% 7-17kDa (form. 6), Top Right) PLGA7525 2.5% 4-15 kDa (form. 9), Bottom Right) PLGA7525 / PCL 50/50 2% 4-15kDa / 2% 14 kDa (form. 12)..jpg) Table 1. Particle formulation loadings, loading efficiencies, and particle size

Table 1. Particle formulation loadings, loading efficiencies, and particle size Figure 2. In vitro differential, cumulative, and cumulative percent HA release. Comparison of (A) PLGA 50:50 (1% w/v) particle formulations of molecular weights 2-6 kDa (formulation 1)and 7-17 kDa (formulation 3) and sodium hydroxide co-encapsulation (formulation 4), (B) PLGA 50:50 (2.5% w/v) particle formulations of molecular weights 2-6 kDa (formulation 2), 7-17 kDa (formulation 5), 54-69 kDa (formulation 7), and 7-17 kDa with sodium hydroxide co-encapsulation (formulation 6), (C) polymer hydrophobicity (PLGA 50:50 < PLGA 75:25 < 50/50 PLGA 75:25 / PCL) (formulation 5, 6, 9, 12), and (D) vaccine amount used in the synthesis and polymer hydrophobicity (PLGA 75:25 < 50/50 PLGA 75:25 / PCL) (formulation 8, 9, 13, 14).

Figure 2. In vitro differential, cumulative, and cumulative percent HA release. Comparison of (A) PLGA 50:50 (1% w/v) particle formulations of molecular weights 2-6 kDa (formulation 1)and 7-17 kDa (formulation 3) and sodium hydroxide co-encapsulation (formulation 4), (B) PLGA 50:50 (2.5% w/v) particle formulations of molecular weights 2-6 kDa (formulation 2), 7-17 kDa (formulation 5), 54-69 kDa (formulation 7), and 7-17 kDa with sodium hydroxide co-encapsulation (formulation 6), (C) polymer hydrophobicity (PLGA 50:50 < PLGA 75:25 < 50/50 PLGA 75:25 / PCL) (formulation 5, 6, 9, 12), and (D) vaccine amount used in the synthesis and polymer hydrophobicity (PLGA 75:25 < 50/50 PLGA 75:25 / PCL) (formulation 8, 9, 13, 14).