Manufacturing and Analytical Characterization - Chemical

Category: Late Breaking Poster Abstract

(M1130-09-60) Use of Robotics and 3D Printing to Assess In Vitro Adhesive Tack Testing of Transdermal Patches

Monday, October 23, 2023

11:30 AM - 12:30 PM ET

- KM

Keb Mosley-Kellum, B.S.

PhD Student

Florida A&M University

TALLAHASSEE, Florida, United States - KM

Keb Mosley-Kellum, B.S.

PhD Student

Florida A&M University

TALLAHASSEE, Florida, United States - SD

Satyanarayan Dev, Ph.D.

Florida A&M University

Tallahassee, Florida, United States - AB

Arvind Bagde, Ph.D. (he/him/his)

Florida A&M University

Tallahassee, Florida, United States - MS

Mandip Singh, Ph.D.

Florida A&M University

Tallahassee, Florida, United States

Presenting Author(s)

Main Author(s)

Co-Author(s)

Purpose: The main objective of the present study was to develop an innovative in vitro testing method for assessing the adhesion properties of topical and transdermal systems (TDS) that is more biorelevant than the current method. Improving the bio-relevance of the in vitro method will allow for using the in vitro testing results to distinguish between clinically significant differences in the adhesion performance of TDS observed during in vivo studies. This improvement would allow for industries to analyze failure modes regarding the adhesion of TDS during the developmental stages and assist the FDA with assessing differences in the adhesion quality and performance between generic TDS and their reference. The current in vitro testing method employs a stainless-steel testing probe (TA-57R) has a significantly higher surface energy ( >700 dyne/cm) than skin (25-50 dyne/cm) to evaluate TDS in vitro. This discrepancy could prove to inaccurately replicate skin conditions when analyzing the tack properties of transdermal patches.

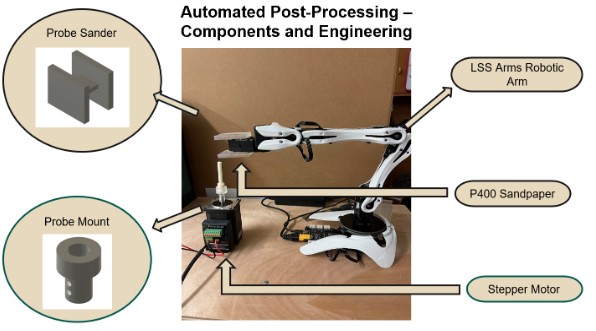

Methods: Fused deposition modeling (FDM) 3D printing was utilized to create testing probes for the texture analyzer composed of different polymers that more closely resemble skin conditions in vitro analysis of transdermal patches. Making this change will produce a more biorelevant testing probe to assess TDS in vitro. Using CAD modeling software, the probe was designed to mimic the dimensions of the stainless-steel probe (TS-57R) (Dimensions: 7mm diameter with 1" radius). Additionally, probe designs with micro-delaminations with dimensions of 2mm, 4 mm, 40um of minor, major axis and depth of ellipse were also prepared to observe their effects on the analyzed tack parameters. Printing filaments of polypropylene (PP), polycarbonate (PC), acrylonitrile butadiene styrene (ABS), and polycarbonate - polybutylene terephthalate (PC-PBT) combination filaments were obtained since they fall within the 25-50 dyne/cm range of surface energy like skin. Additionally, high-density polyethylene (HDPE), polyethylene terephthalate glycol (PETG), and other polymer granules were used to extrude custom made filaments consisting of different combinations of polymers using Felfil filaments maker (Felfil; Turin, Italy).FDM 3D printing parameters such as nozzle temperature, printing bed temperature, printing speed and fan speed were then optimized for the printing of adhesive tack testing probes made with these different filaments. The printing process was also optimized through experimentation with different printing surfaces such as glue, polypropylene sheets, and makerbot build plate tape and printing orientations (horizontal vs. vertical). After printing the probes, Lynxmotion Smart Servo (LSS) robotic arm (4o of freedom, 513.12 mm maximum extension length) was utilized to automate the post manufacturing processing of all printed probes to smooth the testing surface to replicate the testing surface of the TS-57R stainless steel probe. Further, probe surfaces were observed under an optical microscope to check for any deformation.

Results: Our printing results showed that optimal FDM parameters which fell in the range of 250 – 2800 F, 50 – 100 oF, 40 – 80%, and 50 – 100% for nozzle and bed temperature, fan and print speed respectively produced probes with no deformation. The optimal nozzle temperatures for ABS, PP, and PC were found to be 245, 220, and 300oC respectively. Optimal chamber temperatures for ABS, PP, and PC were found to be 93, 40, and 114 oC respectively. Optimal filament extrusion parameters fell in the range of 3-9, 20 – 30, 240 – 260, slow – medium, and 190 – 210 oF for travel speed, spooling speed, fan speed, spooling mode, and extrusion temperature parameters respectively. Our results also showed that orientation of the print (horizontal or vertical) significantly affected the probe print quality. Probes printed in horizontal orientation produced probes with no deformation. Results also showed that we could successfully print probes with micro-delaminated surfaces with dimensions of 2 mm, 4 mm, 40um of minor, major axis and depth of ellipse. Our post processing results revealed that 1-3 minutes processing time could produce smooth surface as shown in figures 2 and 3. Further, automated robotic arm setup enabled the post processing process more efficient and reproducible. Additionally, optical microscopic images of the probe showed smooth surface with no deformation. These finalized probes were then used in probe tack testing of transdermal patches.

Conclusion: In conclusion, this report demonstrates the development of 3D printed probes designed to mimic the skin characteristics which could serve as an improved in vitro model for TDS products. Printed probes of varying surface energies within the range of 20-50 dyme/cm3 were produced to cover the entire range of surface energies for skin. Additionally, probes with micro-delaminations were also produced to determine their effects on tack properties and mimic these types of skin deformations in vitro. These 3D probes can be used in adhesion studies to analyze transdermal patches and conduct in vivo in vitro correlation studies.

Figure 1 shows the developed automated post-processing assembly used to ensure the testing surface of 3D-printed probes made with the Dremel 3D printer are smooth and devoid of deformation.

Figure 1 shows the developed automated post-processing assembly used to ensure the testing surface of 3D-printed probes made with the Dremel 3D printer are smooth and devoid of deformation.  FIgure 2 is a diagram highlighting the proficiency of our automated post-processing method in removing deformations from our 3D-printed probes. The images shown are the side view of our 3D-printed probes obtained via optical microscopy.

FIgure 2 is a diagram highlighting the proficiency of our automated post-processing method in removing deformations from our 3D-printed probes. The images shown are the side view of our 3D-printed probes obtained via optical microscopy. .jpg) Figure 3 compares images of the 3D-modeled probe containing different numbers of elliptical micro-delaminations to the 3D-printed probes produced using those files. This figure shows the capabilities of the MethodX 3D printer in creating probes containing micro-delaminations added to the probes in the 3D model.

Figure 3 compares images of the 3D-modeled probe containing different numbers of elliptical micro-delaminations to the 3D-printed probes produced using those files. This figure shows the capabilities of the MethodX 3D printer in creating probes containing micro-delaminations added to the probes in the 3D model.