Manufacturing and Analytical Characterization - Biomolecular

Category: Poster Abstract

(T1130-08-50) Highly Protein-Loaded Melt Extrudates Produced by Small-Scale Ram and Twin-Screw Extrusion - Evaluation of Extrusion Process Design on Protein Integrity by Experimental and Numerical Approaches

Tuesday, October 24, 2023

11:30 AM - 12:30 PM ET

Katharina Dauer, M.Sc.

Doctoral student

University of Bonn

Bonn, Nordrhein-Westfalen, Germany

Katharina Dauer, M.Sc.

Doctoral student

University of Bonn

Bonn, Nordrhein-Westfalen, Germany- FE

Felix Ellwanger, M.Sc.

Karlsruhe Institute of Technology

Karlsruhe, Baden-Wurttemberg, Germany - KW

Karl G. G. Wagner, Ph.D.

University of Bonn

Bonn, Nordrhein-Westfalen, Germany - HK

Heike P. Karbstein, Ph.D.

Karlsruhe Institute of Technology

Karlsruhe, Baden-Wurttemberg, Germany - ME

M. Azad Emin, Ph.D.

Nexnoa GmbH

Karlsruhe, Baden-Wurttemberg, Germany

Presenting Author(s)

Main Author(s)

Co-Author(s)

Purpose: The biopharmaceutical sector has grown rapidly over the last two decades. However, biopharmaceutics have to be parenterally administered mostly as liquid formulation. Since biopharmaceutics are often not stable in liquid-state, the solid-state is preferred. Lyophilization and spray-drying are the mainly used techniques to convert biopharmaceutics from a liquid- to a solid-state formulation. In the last few years, the application of hot-melt extrusion (HME) was expanded to biopharmaceutics and can be used for solid-state protein stabilization or for production of long-term release systems (e.g., protein-loaded implants) [1,2,3]. As previously published, the use of HME in protein formulation development is still in its early stages. An understanding of HME process parameters and correlation of experimental and simulative data on protein stability was hitherto incompletely considered. This study evaluates the use of small-scale HME (ram extrusion and TSE) to produce protein-loaded extrudates at batch sizes < 3g. The study includes relevant extrusion process parameters to facilitate potential correlations (e.g., screw configuration, screw speed, and mean residence time (MRT)) with experimental data on polymer, and protein characteristics (e.g., heat capacity, unfolding temperature, and protein recovery rate).

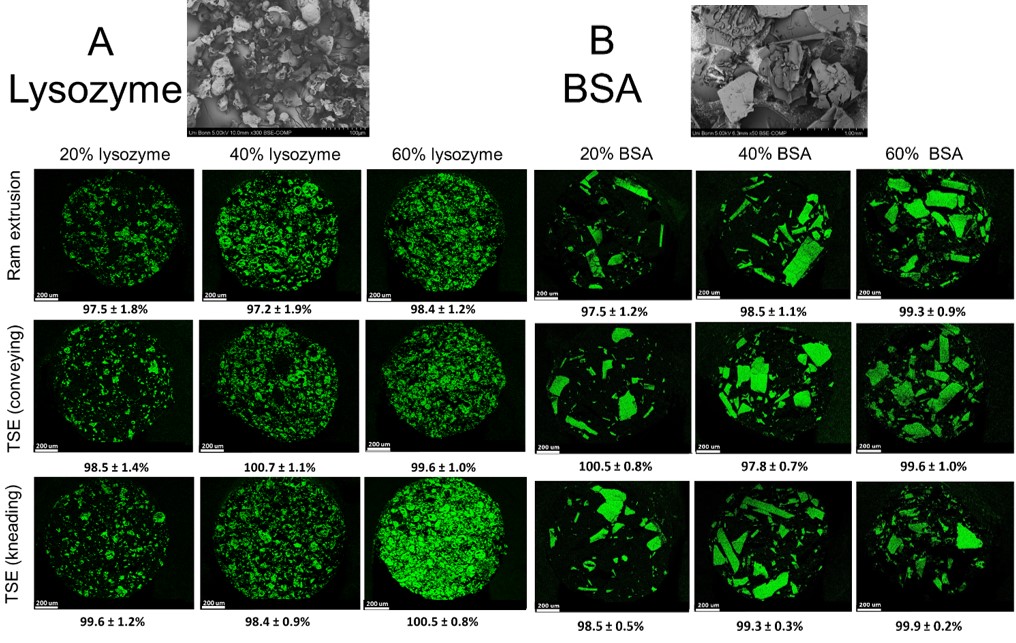

Methods: Physical mixtures (3g) composed of PEG 20,000 and protein powder (lysozyme or BSA: 20, 40, or 60% (w/w)) were either manually fed into a preheated barrel (60-63°C) of a ram extruder or fed via a conveying belt in a 5-mm TSE used with conveying or kneading screw elements (ZE5, Three-Tec). DSC studies (25-230 °C; 10 K/min) were performed with a DSC2 (Mettler Toledo). The samples (∼10 mg) were weighed in pinned aluminum crucibles. The heat capacity was determined using a multi-frequency temperature modulation (TOPEM® mode; 25-100°C; 2 K/min). Protein recovery rates were characterized by RP-HPLC (Agilent 1100 series, RP-C18 Nucleosil, 125×4 mm, MN) and linear gradient method (mobile phases: (A: 100/0/0.1, B: 0/100/0.1, V/V water/acetonitrile/trifluoroacetic acid; 0-10 min; 5-95%B; 1 mL/min; column temperature: 30°C; 220 and 280 nm). Visual protein particle distribution was examined by elemental nitrogen-mapping of cross sections of extrudates (Hitachi S-2700, EDX spectroscopy). 3D simulation of die and screw sections was performed with Ansys Polyflow® (Ansys Inc). 1D simulation software Ludovic® V6.0 (Sciences Computers Consultants) was used for calculation of parameters along the screw profile (e.g., temperature, MRT).

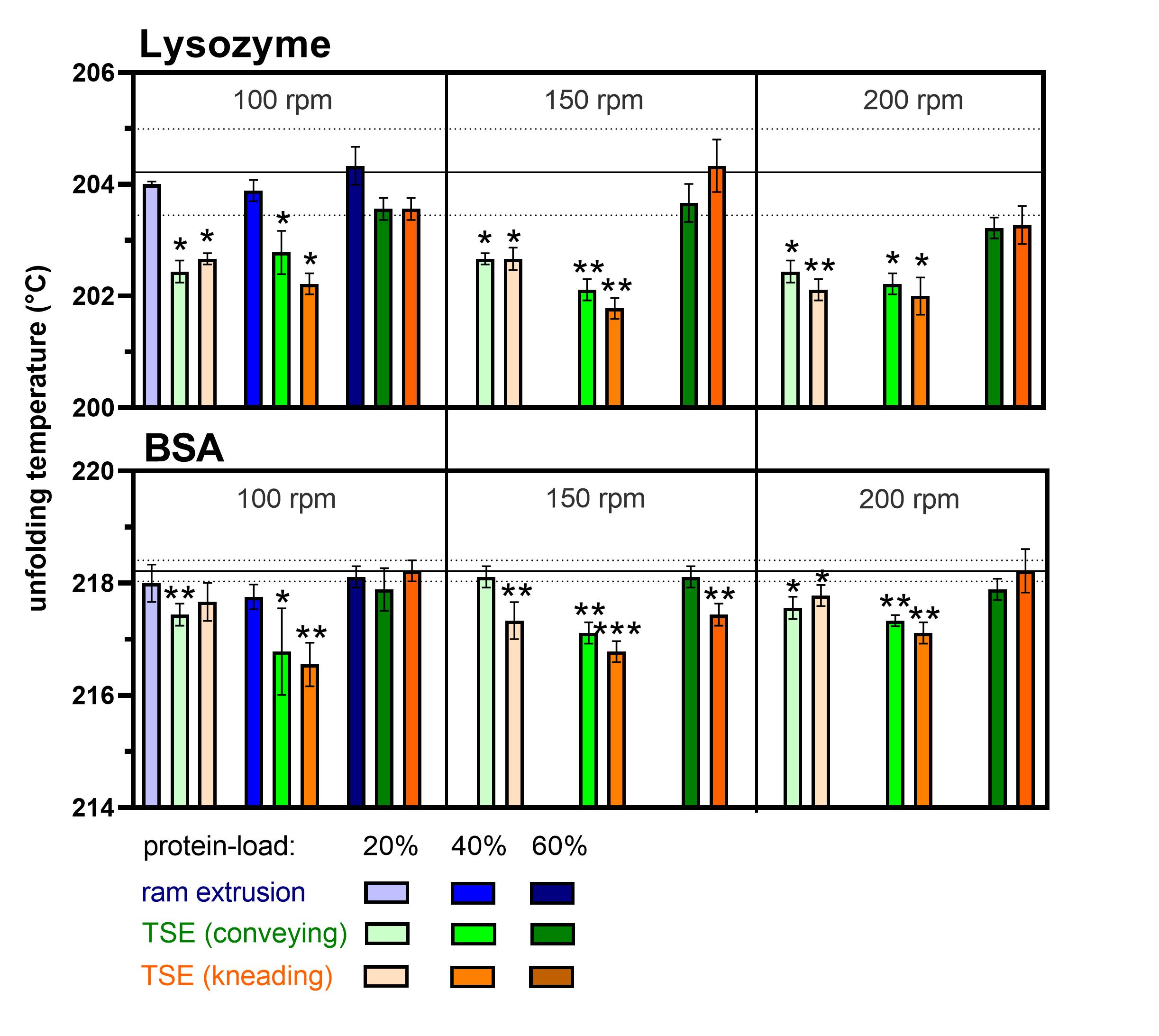

Results: As mechanical stress in extrusion processing may lead to degradation of proteins, 3D software was used to characterize mechanical stress profiles during ram extrusion and TSE. The highest shear rates were found close to the wall and gradually decreased towards the center of the die channel (Figure 1). For TSE the highest shear rates were present in the screw section and particularly in the gap between the screws and the screw and the barrel. The increased shear rate for the kneading element can be attributed to different flow profiles resulting from the restriction of 90° kneading discs. Accordingly, it can be assumed that degradation of protein particles was more likely to occur in TSE, especially when a kneading element was used, than in ram extrusion processing. In this study, lysozyme and BSA particles could be regarded as fillers during extrusion, since the particle size of the used protein powders was identical for the starting material and particles detected in the cross section of extrudates (Figure 2). Ram extrusion facilitates sufficient dispersion of protein particles for all protein-loads. The distributive mixing effects of TSE were not necessary for the production of protein-loaded extrudates and TSE were thus not superior compared to ram extrusion. The simulations raised the expectation of particle grinding during extrusion, especially when TSE is used. However, mechanical stress generated during ram extrusion and TSE was not high enough to break neither the lysozyme nor the BSA particles. Ram extrusion had the lowest impact on unfolding temperatures (Figure 3) which is in agreement with results of 3D simulation. That die-induced stress was higher for the ram than for the TSE die, still much lower than the screw induced stress. A protein-load effect on the unfolding temperature was observed for TSE-extrudates. Interestingly a higher protein-load of 60% was protective resulting in a less pronounced decrease of unfolding temperatures.

Conclusion: The applied simulations proved to be valuable tools for the evaluation of extrusion process design and provided important insights into extrusion processing optimization and potential scale-up challenges at small-scale levels. Ram extrusion was identified as favored method for the production of stable protein-loaded extrudates, since the thermomechanical stress was low and still a homogenous distribution of protein particles over the cross section was achieved. No simple 1D simulation model is available for ram extrusion thus, 3D simulations had to be employed for crucial process steps. As the die in ram extrusion was identified as the most critical process area, this limitation is negligible. In contrast for TSE, 1D identifies critical process steps while 3D simulations boost the mechanistic understanding.

References: 1. Cossé, A. et al., Hot Melt Extrusion for Sustained Protein Release: Matrix Erosion and In Vitro Release of PLGA-Based Implants. AAPS PharmSciTech, 1;18(1):15-26 (2017).

2. Ghalanbor, Z. et al., Improved Lysozyme Stability and Release Properties of Poly(lactide-co-glycolide) Implants Prepared by Hot-Melt Extrusion. Pharm. Res. 27, 371–379. (2010).

3. Stanković, M., Frijlink, H. W. & Hinrichs, W. L. J. Polymeric formulations for drug release prepared by hot melt extrusion: application and characterization. Drug Discov. Today 20, 812-823 (2015).

Acknowledgements: We would like to thank the German Research Foundation (DFG) for funding within priority program SPP 1934.

.jpg) Color plots of the shear rate distribution of A ram extruder die B twin-screw extruder die; Color plots of the shear rate distribution of C TSE conveying elements (5 mm pitch) die D TSE 90° kneading elements.

Color plots of the shear rate distribution of A ram extruder die B twin-screw extruder die; Color plots of the shear rate distribution of C TSE conveying elements (5 mm pitch) die D TSE 90° kneading elements. SEM-images of the used protein powder; protein particle distribution by SEM-EDX and elemental mapping of nitrogen (green spots) on cross-section of 20, 40, and 60% protein-loaded extrudates (A lysozyme and B BSA) prepared by ram or twin-screw extrusion (screw speed: 150 rpm) at 63°C and protein recovery rates determined by RP-HPLC (n = 3) below the SEM-EDX-images. The scale bar of SEM-images corresponds to 200 μm.

SEM-images of the used protein powder; protein particle distribution by SEM-EDX and elemental mapping of nitrogen (green spots) on cross-section of 20, 40, and 60% protein-loaded extrudates (A lysozyme and B BSA) prepared by ram or twin-screw extrusion (screw speed: 150 rpm) at 63°C and protein recovery rates determined by RP-HPLC (n = 3) below the SEM-EDX-images. The scale bar of SEM-images corresponds to 200 μm. Unfolding temperatures of 20, 40, and 60% protein-loaded (lysozyme and BSA) extrudates prepared by ram extrusion (blue) or TSE with only conveying screw configuration (green), or screws containing a single 90° kneading element (orange) at 100, 150, or 200 rpm screw speed, at 63°C; error bars represent the standard deviation of three measurements for the unfolding temperature by DSC; the line shows the melting temperature of the unprocessed protein (reference) and the dotted lines represent the standard deviation (n = 3); statistical significance is compared to the reference and depicted by asterisks (*): * p < 0.05, ** p < 0.01, *** p < 0.001.

Unfolding temperatures of 20, 40, and 60% protein-loaded (lysozyme and BSA) extrudates prepared by ram extrusion (blue) or TSE with only conveying screw configuration (green), or screws containing a single 90° kneading element (orange) at 100, 150, or 200 rpm screw speed, at 63°C; error bars represent the standard deviation of three measurements for the unfolding temperature by DSC; the line shows the melting temperature of the unprocessed protein (reference) and the dotted lines represent the standard deviation (n = 3); statistical significance is compared to the reference and depicted by asterisks (*): * p < 0.05, ** p < 0.01, *** p < 0.001.