Formulation and Delivery - Chemical

Category: Poster Abstract

(T1130-11-75) Sonoprecipitation Synthesis of a Multifunctional Prodrug Nanosuspension Using a Quality by Design Approach

- TR

Tomas Roldan, BA

Rutgers University Ernest Mario School of Pharmacy

Piscataway, New Jersey, United States - TR

Tomas Roldan, BA

Rutgers University Ernest Mario School of Pharmacy

Piscataway, New Jersey, United States - SL

Shike Li, M.D.

Rutgers University Ernest Mario School of Pharmacy

Piscataway, New Jersey, United States - CG

Christophe Guillon, Ph.D.

Lehigh University

Bethlehem, Pennsylvania, United States - NH

Ned D. Heindel, Ph.D.

Lehigh University

Bethlehem, Pennsylvania, United States - JL

Jeffrey D. Laskin, Ph.D.

Rutgers University School of Public Health

Piscataway, New Jersey, United States - DG

Dayuan Gao, Ph.D.

Rutgers University Ernest Mario School of Pharmacy

Piscataway, New Jersey, United States - PS

Patrick J. Sinko, Ph.D.

Rutgers University Ernest Mario School of Pharmacy

Piscataway, New Jersey, United States

Presenting Author(s)

Main Author(s)

Co-Author(s)

Purpose: The development of effective pharmaceuticals for poorly water-soluble drugs is challenging due to limited solubility and bioavailability. One innovative strategy to address this is the use of nanosuspensions (NSs), which are formulations of nano-sized drug particles suspended in a dispersion medium. The small particle size of NSs lead to an increase in surface area, which enhances drug dissolution and bioavailability. In this study, a quality by design approach was used in the sonoprecipitation NS synthesis of NDH-4338, a prodrug comprised of cyclooxygenase, acetylcholinesterase, and inducible nitric oxide synthase inhibitors. This study evaluated critical processing parameters (CPP) of sonoprecipitation, such as antisolvent/solvent ratio (A/S), and critical material attributes (CMA) including drug loading (DL) and drug-stabilizer ratio (D/S), to determine their impact on critical quality attributes (CQA) such as particle size, polydispersity index (PDI), and encapsulation efficiency (EE). A response surface method using Box-Behnken experimental design was used to optimize these factors. The model was fit with statistical satisfaction and successfully predicted the CMA and CPP conditions that were used to prepare the optimized NS, which was validated by Test Equivalence with a 95% confidence interval. Two optimization approaches led to a significant decrease in the NS defect rate, as well as a 3-fold increase in optimized NS dissolution rate compared to bulk drug powder. These findings demonstrate the effectiveness of the Quality by Design approach in predicting the optimal CMA and CPP conditions to minimize the size of NDH-4338 NS.

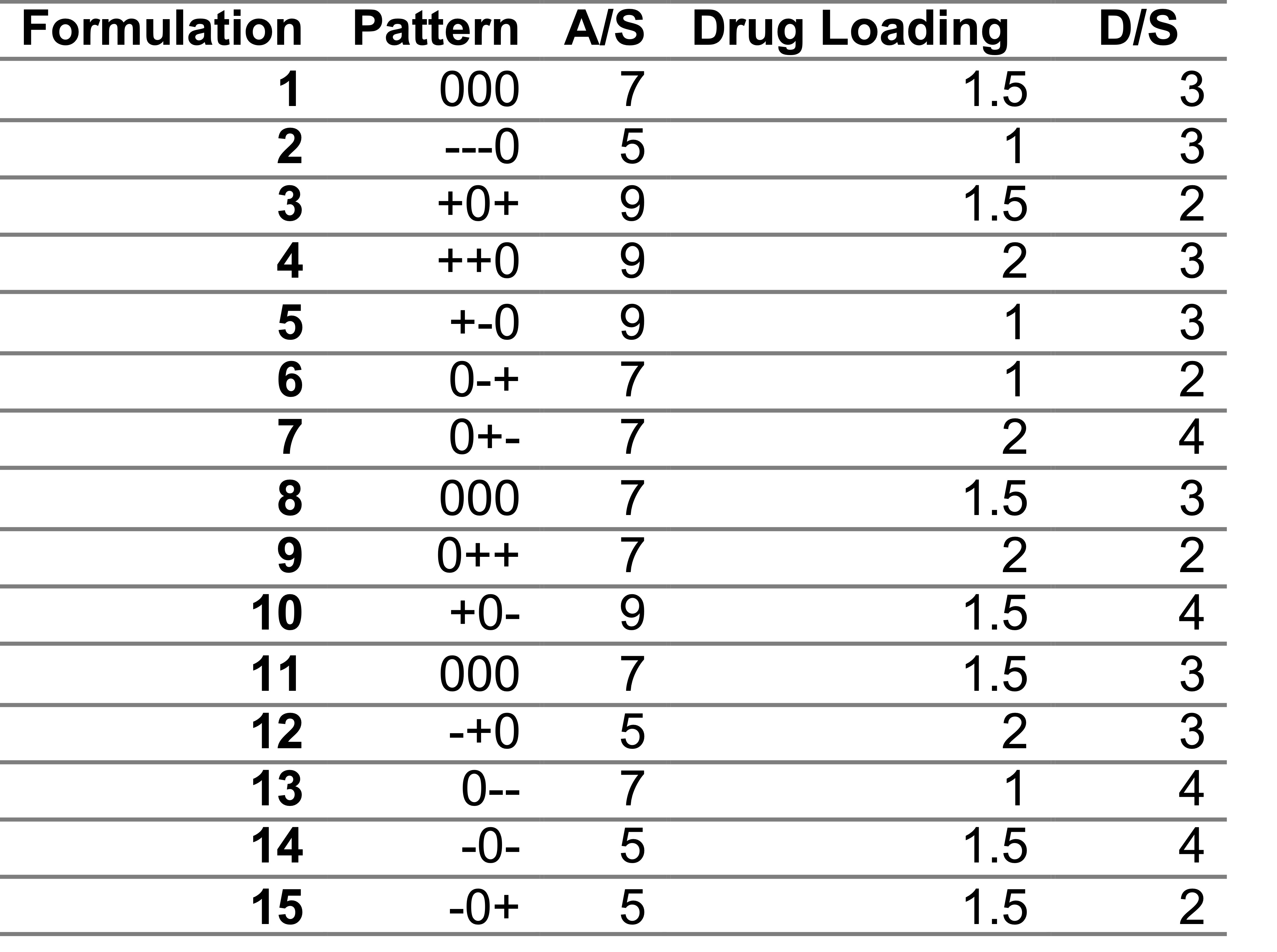

Methods: NSs were prepared via sonoprecipitation in the presence of a d-α-tocopheryl polyethylene glycol 1000 succinate (Vitamin E TPGS) aqueous stabilizer solution. Size and PDI were measured by dynamic light scattering (DLS) and encapsulation efficiency was determined by HPLC. An initial evaluation was performed to determine to explore the factor range for design of experiments (DOE). Three parameters, A/S, DL, and D/S, were further subjected to a Box-Behnken design of experiment and response surface methodological analysis using JMP Pro 16 to minimize drug crystal size. To validate the model, the optimized formulation was prepared four times to determine if the experimentally derived drug crystal sizes were statistically equivalent to the predicted size. In vitro dissolution testing of the bulk drug powder versus the optimized formulation was performed to determine if the NS approach enhanced the dissolution rate of NDH-4338.

Results: For the Box-Behnken design, the crystal size ranged from 29.90-103.5 nm, the PDI ranged from 0.002-0.365, and the EE ranged from 78.1- 99.7%. A standard least squares fit of the model produced an R squared of 0.93 with a 0.0061 p-value, meeting statistical validation criteria. There was no lack of fit or indication of any potential outliers, and variance inflation factor estimates confirmed that each parameter could be included in the model. After maximizing the desirability function, the defect rate for the 10-50 nm spec limits decreased from 42.2 to 8.1%. A Gaussian process script of the Monte Carlo simulation shows factor conditions that further lowered the defect rate to 6.5%, with the optimal conditions being an A/S of 6.2, DL of 2% w/w, and D/S of 2.8. For model validation, a Test Equivalence distribution analysis with a 95% confidence interval determined that the mean of four samples prepared at the optimal conditions was equivalent to the predicted size. In vitro dissolution of the optimized nanosuspension formulation showed a 3-fold increase in dissolution rate after 15 minutes compared to the bulk drug powder.

Conclusion: A DOE approach successfully predicted optimal CMA and CPP conditions to minimize the size of NDH-4338 NSs. The model met quality criteria by various methods of statistical evaluation and the optimal formulation showed an increased dissolution rate in comparison to bulk powder. These findings suggest that the use of a comprehensive optimization process can lead to the production of high-quality nanocrystals with improved properties, which could have significant implications for drug delivery and development. Future work will include the incorporation of the nanocrystals into a permeation-enhancing vehicle and therapeutic evaluation of the formulation using the depilatory double-disc (DDD) mouse model.

Acknowledgements: Funding information: This research was supported by Countermeasures Against Chemical Threats, NIH grant AR055073, and the Parke‐Davis Endowed Chair in Pharmaceutics and Drug Delivery. Conflict of Interest Statement: The authors declare that there are no conflicts of interest.

Fig. 1. A Box-Behnken Design (BBD) of experiment was constructed to minimize nanocrystal size. Three critical factors were selected from the initial evaluation data, antisolvent-solvent ratio (A/S), drug loading, and drug-to-stabilizer ratio (D/S). For the experimental design, a BDD was selected, as prediction profilers demonstrate that power analyses of BBDs are better suited at the edges of critical factor ranges than other design types. Using JMP Pro 16, 15 runs were generated with 3 center points.

Fig. 1. A Box-Behnken Design (BBD) of experiment was constructed to minimize nanocrystal size. Three critical factors were selected from the initial evaluation data, antisolvent-solvent ratio (A/S), drug loading, and drug-to-stabilizer ratio (D/S). For the experimental design, a BDD was selected, as prediction profilers demonstrate that power analyses of BBDs are better suited at the edges of critical factor ranges than other design types. Using JMP Pro 16, 15 runs were generated with 3 center points. .jpg) Fig. 2. Two optimization strategies lowered the predicted drug crystal size and defect rate. By using the maximum desirability function, the defect rate for the optimized factor settings to produce nanocrystals that fall within the 10-50 nm spec limits was lowered from 42.2 to 8.1%. After running a Gaussian process script of the Monte Carlo simulation, the defect rate was further lowered to 6.5%, with the optimal settings being antisolvent/solvent ratio (A/S) of 6.2, drug loading (DL) of 2% w/w, and drug to stabilizer ratio (D/S) of 2.8.

Fig. 2. Two optimization strategies lowered the predicted drug crystal size and defect rate. By using the maximum desirability function, the defect rate for the optimized factor settings to produce nanocrystals that fall within the 10-50 nm spec limits was lowered from 42.2 to 8.1%. After running a Gaussian process script of the Monte Carlo simulation, the defect rate was further lowered to 6.5%, with the optimal settings being antisolvent/solvent ratio (A/S) of 6.2, drug loading (DL) of 2% w/w, and drug to stabilizer ratio (D/S) of 2.8. .jpg) Fig. 3. A Test Equivalence distribution analysis validates the model performance. The crystal sizes of four formulations prepared at the optimal factor settings were determined to be statistically equivalent to the predicted size, with a 95% confidence interval.

Fig. 3. A Test Equivalence distribution analysis validates the model performance. The crystal sizes of four formulations prepared at the optimal factor settings were determined to be statistically equivalent to the predicted size, with a 95% confidence interval.