Manufacturing and Analytical Characterization - Biomolecular

Category: Poster Abstract

(M1130-08-49) Identifying and Characterizing the Effect of Critical Processing Parameters in Double Emulsion Poly(lactic-co-glycolic) Acid Microparticle Fabrication

Monday, October 23, 2023

11:30 AM - 12:30 PM ET

Elizabeth Bentley, BS

PhD Candidate

University of Pittsburgh

Pittsburgh, Pennsylvania, United States

Elizabeth Bentley, BS

PhD Candidate

University of Pittsburgh

Pittsburgh, Pennsylvania, United States- SB

Stephen Balmert, Ph.D.

University of Pittsburgh

Pittsburgh, Pennsylvania, United States - MP

Michael Pezzillo

University of Pittsburgh

Pittsburgh, Pennsylvania, United States - SS

Stacia Subick

University of Pittsburgh

Pittsburgh, Pennsylvania, United States - SL

Steven Little, Ph.D.

University of Pittsburgh

Pittsburgh, Pennsylvania, United States

Presenting Author(s)

Main Author(s)

Co-Author(s)

Purpose: In the past several decades, controlled drug delivery strategies have emerged has a viable solution to address common limitations of standard pharmaceuticals. Our group has demonstrated the efficacy of these systems, specifically polymeric microparticles (MPs), in many inflammatory disease models [1-4]. While there are many preclinical research studies that utilize double emulsion MPs as a delivery vehicle, there are limited FDA-approved products [5]. One potential barrier to translation of these technologies is a lack of understanding of the manufacturing process of double emulsion MPs, hindering scale-up from small batches (often found in an academic research setting) to large-scale manufacturing (more applicable for industry) [6, 7]. In this study, we sought to address this knowledge gap by identifying critical processing parameters (CPPs) in the manufacturing process of unloaded (no cargo) double emulsion poly(lactic-co-glycolic) (PLGA) MPs by utilizing a quality by design (QbD) approach. Given that particle surface area to volume ratio is known to impact many critical quality attributes (CQAs), MP size was chosen as the main outcome variable for this study [8, 9]. For translational purposes, we also sought to elucidate relationships between CPPs and CQAs of protein-loaded MPs. Altogether, this study elucidates several important parameters that should considered during scale-up of these technologies.

Methods: Using a design of experiments (DOE) approach, we first explored the impact of CPPs on unloaded (no protein) double emulsion MPs size given that size can greatly impact CQAs [9]. Design-ExpertÒ Stat-Ease was used to generate a response surface methodology (RSM) with a two-level, split-plot design, allowing for hard-to-change variables to be incorporated. A D-optimal design (instead of L-optimal) was used, as it places a greater emphasis on identifying significant processing parameters (rather than predicting trends). 8 independent variables were explored: (1) aqueous phase volume, (2) polymer amount, (3) organic solvent volume, (4) sonication amplitude, (5) outer aqueous phase concentration, (6) homogenization time, (7) solvent evaporation speed, and (8) solvent evaporation duration. The generated RSM design resulted in 60 double emulsion MP batches with distinct input processing parameters. MPs were fabricated using a double emulsion solvent evaporation method, following which they were sized with volume impedance measurements. A log transformation was utilized to normalize data, following which an analysis of variance (ANOVA) was conducted to determine significant single factor and interaction effects. After identifying significant CPPs, protein-loaded MPs, specifically MPs encapsulating recombinant human CCL22 (rhCCL22-MPs), a chemokine for regulatory T cells (Tregs), were fabricated to explore the impact of CPPs on additional CQAs. Scanning electron microscopy (SEM) was used to analyze microparticle size, surface morphology, and inner occlusion size/distribution.

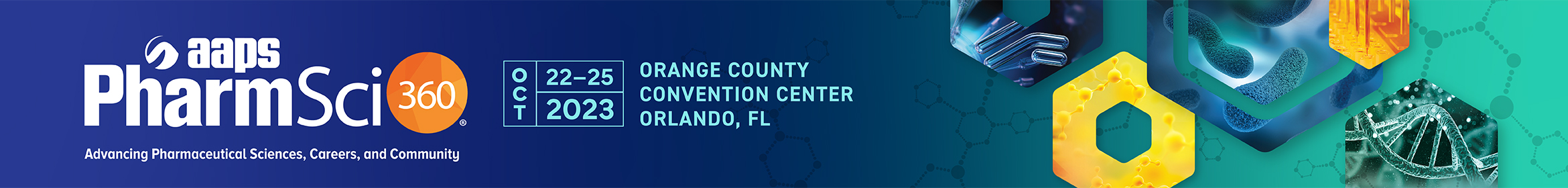

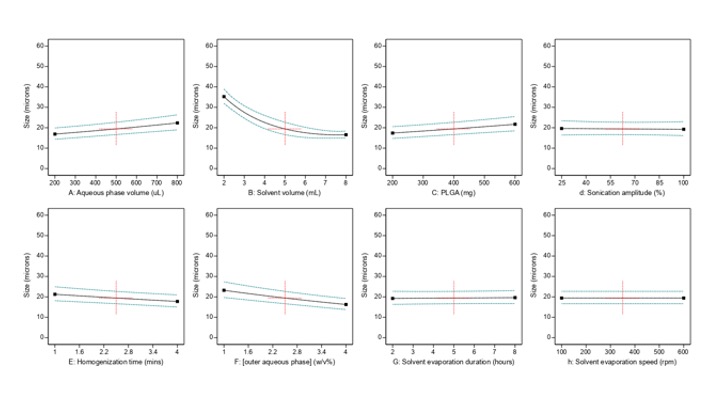

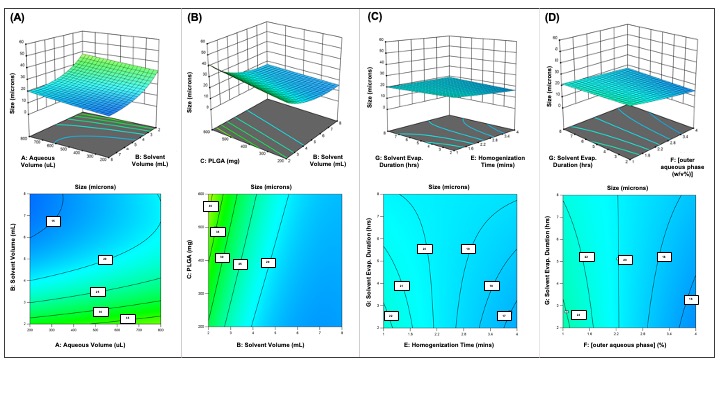

Results: After model reduction, several single factor and interaction variables were found to have a significant impact on unloaded-MP size. Significant single factor effects include aqueous phase volume (p < 0.0001), solvent volume (p < 0.0001), PLGA amount (p = 0.0001), homogenization time (p = 0.0016), and concentration of the outer aqueous phase (p < 0.0001). Notably, as aqueous phase volume and PLGA amount increase, MP size increases (Figure 1). However, as homogenization time and the concentration of the outer aqueous phase decrease, MP size decreases. The relationship between solvent volume and size is a quadratic relationship, with size decreasing non-linearly as solvent volume increases. For interaction effects, the interaction between aqueous phase volume and solvent volume (p = 0.0479), solvent volume and PLGA amount (p = 0.0326), homogenization time and solvent evaporation duration (p = 0.0431), and [outer aqueous phase] and solvent evaporation duration (p = 0.0243), were found to be significant (Figure 2). Further exploration of the interaction between solvent volume and PLGA amount demonstrates the impact of these variables on MP CQAs. For instance, at lower solvent volumes (2 mL), the amount of PLGA has a significant impact on size (Figure 3). However, at higher solvent volumes, the amount of PLGA does not have a significant impact on size. Furthermore, as DCM volume increases, inner occlusion size of rhCCL22-MPs increases (Figure 3B). SEM images of rhCCL22-MPs also demonstrate an increase in overall PLGA density as polymer amount increases.

Conclusion: Altogether, these results suggest that there are several single factor and interaction effects in double emulsion MP fabrication that impact MP CQAs. Significant single factor effects include aqueous phase volume, solvent volume PLGA amount, homogenization time, and the concentration of the outer aqueous phase. There are also numerous interaction effects that impact MP CQAs, including the interaction between solvent volume and PLGA amount. Furthermore, it can be concluded that there is a much greater impact of PLGA amount on MP size at lower solvent volumes when compared to higher solvent volumes. Using this preliminary data as a framework, future studies will explore the impact of these significant parameters on additional CQAs of rhCCL22-MPs, such as encapsulation efficiency and protein release kinetics.

References: 1. Fisher, J.D., et al., In situ recruitment of regulatory T cells promotes donor-specific tolerance in vascularized composite allotransplantation. Sci Adv, 2020. 6(11): p. eaax8429.

2. Balmert, S.C., et al., In vivo induction of regulatory T cells promotes allergen tolerance and suppresses allergic contact dermatitis. J Control Release, 2017. 261: p. 223-233.

3. Fisher, J.D., et al., Treg-inducing microparticles promote donor-specific tolerance in experimental vascularized composite allotransplantation. Proc Natl Acad Sci U S A, 2019. 116(51): p. 25784-25789.

4. Glowacki, A.J., et al., Prevention of inflammation-mediated bone loss in murine and canine periodontal disease via recruitment of regulatory lymphocytes. Proc Natl Acad Sci U S A, 2013. 110(46): p. 18525-30.

5. Wang, Y., et al., FDA's Poly (Lactic-Co-Glycolic Acid) Research Program and Regulatory Outcomes. AAPS J, 2021. 23(4): p. 92.

6. Bentley, E.R. and S.R. Little, Local delivery strategies to restore immune homeostasis in the context of inflammation. Adv Drug Deliv Rev, 2021. 178: p. 113971.

7. Yu, L.X., et al., Understanding pharmaceutical quality by design. AAPS J, 2014. 16(4): p. 771-83.

8. Makadia, H.K. and S.J. Siegel, Poly Lactic-co-Glycolic Acid (PLGA) as Biodegradable Controlled Drug Delivery Carrier. Polymers (Basel), 2011. 3(3): p. 1377-1397.

9. Han, F.Y., et al., Bioerodable PLGA-Based Microparticles for Producing Sustained-Release Drug Formulations and Strategies for Improving Drug Loading. Front Pharmacol, 2016. 7: p. 185.

Acknowledgements: E. Bentley was supposed by the National Institutes of Health [grant number T32 AI 74490; NIH/NIAID] during this project.

Figure 1. Impact of increasing/decreasing manufacturing variables on microparticle size. Aqueous phase volume, solvent volume, amount of PLGA, homogenization time and concentration of the outer aqueous phase were found to have a significant impact on blank double emulsion microparticle size (p < 0.5).

Figure 1. Impact of increasing/decreasing manufacturing variables on microparticle size. Aqueous phase volume, solvent volume, amount of PLGA, homogenization time and concentration of the outer aqueous phase were found to have a significant impact on blank double emulsion microparticle size (p < 0.5). Figure 2. Factor Effects. Impact of increasing/decreasing manufacturing variables on microparticle size. 3D surface and contour plots for the interactions of (A) aqueous phase volume (uL) and solvent volume (mL), (B) solvent volume (mL) and the amount of PLGA used (mg), (C) homogenization time (mins) and solvent evaporation duration (hrs) and (D) [outer aqueous phase (w/v%)] and solvent evaporation duration (hrs). These interaction effects were found to be significant (p < 0.5),

Figure 2. Factor Effects. Impact of increasing/decreasing manufacturing variables on microparticle size. 3D surface and contour plots for the interactions of (A) aqueous phase volume (uL) and solvent volume (mL), (B) solvent volume (mL) and the amount of PLGA used (mg), (C) homogenization time (mins) and solvent evaporation duration (hrs) and (D) [outer aqueous phase (w/v%)] and solvent evaporation duration (hrs). These interaction effects were found to be significant (p < 0.5), Figure 3. Increasing solvent volume and PLGA amount alters microparticle size, inner occlusion size, and overall microparticle density. (A) Interaction plot generated by Design-Expert demonstrates decreasing microparticle size with increasing solvent volume regardless of PLGA amount. At lower solvent volumes, amount of PLGA has a significant impact on microparticle size. (B) Scanning electron microscopy (SEM) images of rhCCL22-MPs depict increased inner occlusion size with increased solvent volume, and increased density with increased PLGA amount.

Figure 3. Increasing solvent volume and PLGA amount alters microparticle size, inner occlusion size, and overall microparticle density. (A) Interaction plot generated by Design-Expert demonstrates decreasing microparticle size with increasing solvent volume regardless of PLGA amount. At lower solvent volumes, amount of PLGA has a significant impact on microparticle size. (B) Scanning electron microscopy (SEM) images of rhCCL22-MPs depict increased inner occlusion size with increased solvent volume, and increased density with increased PLGA amount.